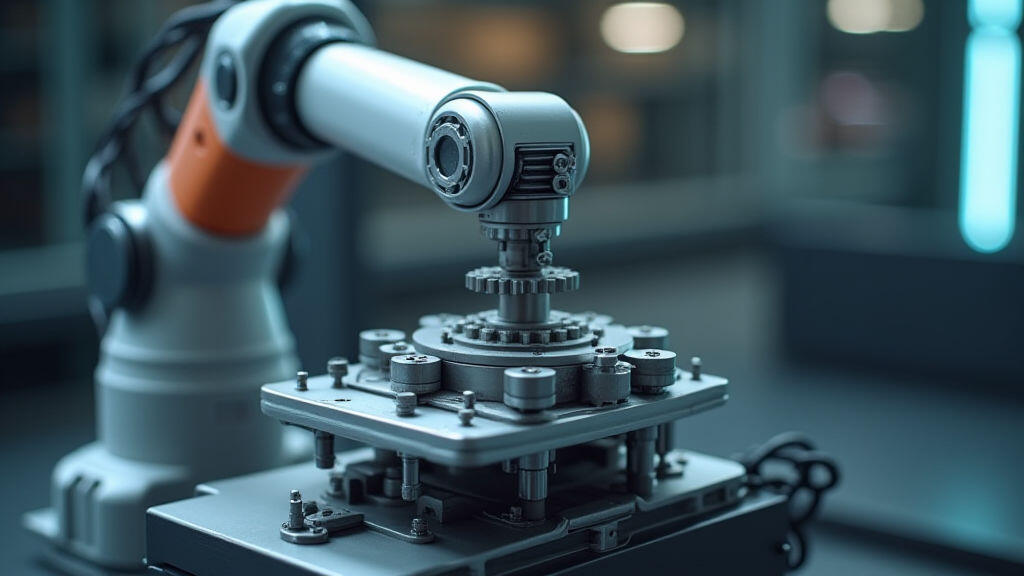

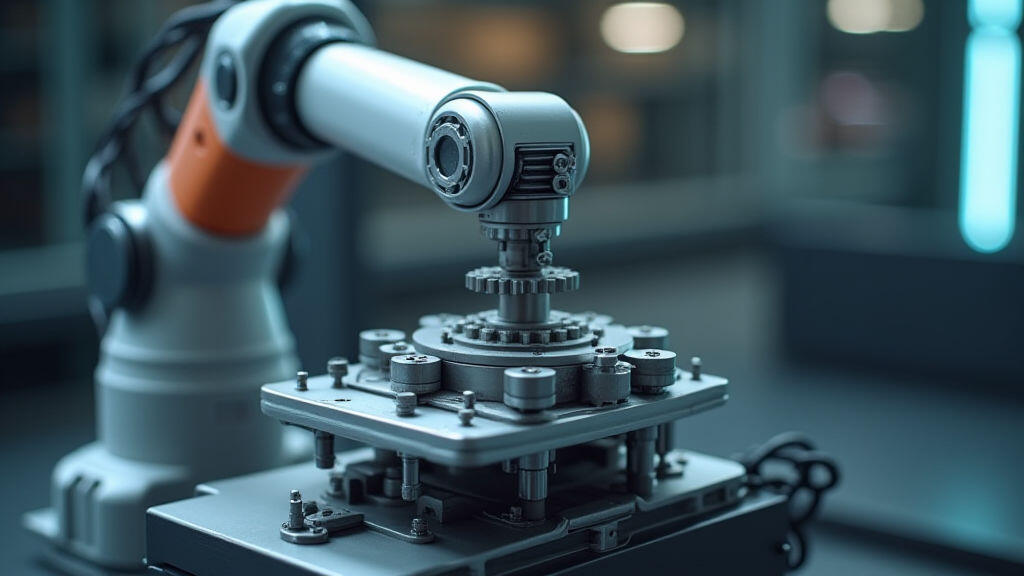

The robotics industry is experiencing explosive growth, driven by advancements in Artificial Intelligence (AI), automation, and the increasing demand for efficient and reliable solutions across various sectors – from manufacturing and logistics to healthcare and agriculture. At the heart of almost every robotic application lies the gear motor, a critical component responsible for translating electrical energy into mechanical motion. Choosing the right gear motor brand is not just a purchase; it’s a strategic investment that directly impacts the performance, lifespan, and overall success of robotic systems.

This article delves into the key parameters robotics enterprises should carefully consider when selecting a gear motor brand, ensuring optimal performance and mitigating potential risks in this dynamic field. With the rise of edge computing and real-time decision-making in robotics, the demands on motor reliability and precision are higher than ever.

The foundational consideration is, naturally, the torque and speed requirements of the robotic application. Each robot has unique needs dictated by its intended tasks. A robotic arm designed for delicate assembly work will require high precision and lower torque compared to a heavy-duty industrial robot handling large objects. Conversely, a mobile robot navigating uneven terrain demands adequate torque to overcome obstacles.

Torque: Measured in Newton-meters (Nm) or inch-pounds (in-lb), torque represents the rotational force. Insufficient torque leads to sluggish performance or complete system failure. Robotics businesses should meticulously analyze the load the motor will be driving, including static and dynamic loads, to accurately determine the required torque. Over-specifying torque can lead to unnecessary costs, while under-specifying results in compromised functionality.

Speed: Measured in revolutions per minute (RPM), speed determines the robot's operational tempo. Higher speeds are necessary for tasks requiring rapid movement, while lower speeds are suitable for delicate manipulations. The motor’s speed must be aligned with the robot’s kinematic chain and the desired task performance.

Gearbox efficiency is a crucial factor influencing overall system performance and cost. Efficiency represents the ratio of mechanical power output to electrical power input. A highly efficient gearbox minimizes energy waste as heat, leading to reduced operating costs and extended motor lifespan.

Efficiency Ratings: Gearbox manufacturers typically provide efficiency ratings, often ranging from 85% to over 95%. Higher efficiency gearboxes are particularly important in battery-powered mobile robots or applications with stringent power budgets.

Load Dependence: Gearbox efficiency isn’t constant. It varies depending on the load. Robotics enterprises should consider efficiency curves provided by the manufacturer to understand performance under different operating conditions. Also, consider the type of gear system (spur, helical, planetary) as each has its own efficiency profile. Planetary gearboxes are generally the most efficient.

Several motor types are commonly used in robotics, each with its strengths and weaknesses. The choice depends on factors like torque requirements, speed range, and application environment.

The advent of integrated motor-gearbox units like those offered by MES-Drive highlights the trend toward simplified system design and optimized performance.

Robotics applications often demand high precision and accuracy in movement. This is crucial for tasks like delicate assembly, medical procedures, and advanced manipulation.

Robots often operate in harsh environments, demanding robust and reliable components. The gear motor is a critical component in this regard.

The gear motor must be compatible with the robot's control system. This includes factors like voltage requirements, communication protocols (e.g., CAN bus, EtherCAT), and available control signals.

Beyond the initial purchase, vendor support and service are crucial for long-term success.

The integration of AI and edge computing is reshaping the robotics landscape. This trend demands gear motors that are not only powerful and precise but also energy-efficient and capable of real-time control. MES-Drive is actively investing in developing gear motors with integrated sensors and intelligent control algorithms to meet these evolving needs. Future advancements will focus on optimizing motor performance through predictive maintenance, improving energy efficiency through AI-powered control schemes, and enhancing robustness for operation in challenging environments. The adoption of these technologies will enable more autonomous, adaptable, and reliable robotic systems across a wide range of industries. The growing demand for human-robot collaboration, facilitated by increasingly agile and responsive robots, creates significant opportunities for gear motor manufacturers willing to embrace innovation.

Leave A Reply

Your email address will not be published. Required fiels are marked